(Photo credits : www.india.com)

(Photo credits : www.india.com)The Covid-19 pandemic has highlighted and exacerbated shortcomings in our healthcare infrastructure and medical oxygen supply systems in India. The aggressive second wave of the pandemic overwhelmed the country, with hospitals unable to arrange adequate oxygen supply for the mounting case numbers, and patients’ family members desperately looking for alternate sources.

Hospital data from the second wave shows that more than 55% of Covid admissions required supplemental oxygen during treatment. At the wave’s peak, India needed nearly 16 million cubic meters of oxygen , or more than 21,000 metric tons/day. There was an extremely large supply-demand gap with India’s daily domestic production being just around 9,000 metric tons.

Even with efforts being made to ramp up production to meet the demand, quick, safe delivery and logistics of medical oxygen supply is a major challenge. This is due to limited availability of cryogenic tankers, storage complications in hospitals and geographic concentration of major O2 generation plants in the country.

(Photo credits: www.hindustantimes.com)

(Photo credits: www.hindustantimes.com)With scientists warning about an inevitable and imminent third wave, India’s hospitals need to be better prepared to deal with another possible surge in cases. Necessary steps need to be urgently initiated to ensure that the O2 crisis does not repeat itself. An optimal solution is for hospitals to be self reliant by setting up onsite oxygen generation plants.

Many state governments across the country have passed a mandatory ruling for hospitals with more than 100 beds to setup their own oxygen plants at twice the normally required capacity, to ensure there is no shortage. The central government also recently announced provision of a 100% guarantee cover for loans of upto Rs 2 Cr to hospitals, for this purpose.

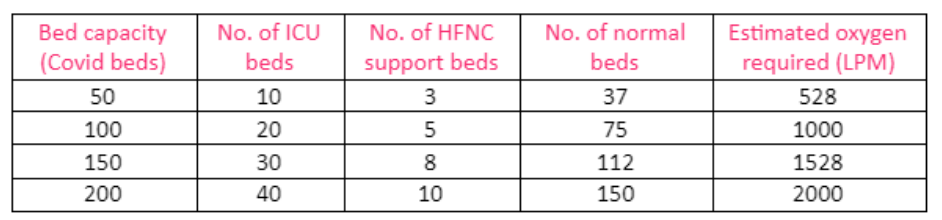

Oxygen supply requirements such as the amount of O2 required, flow rate and O2 purity levels depend on the severity of the case in Covid patients . The patient’s age, history of lung disease, other chronic ailments and the type of treatment administered also impact the patient’s oxygen requirements. It generally ranges from 3-4 LPM (liters per minute) for moderate cases, 10-20 LPM for ICU patients and upto 60 LPM for patients on HFNC support (High flow nasal cannula).

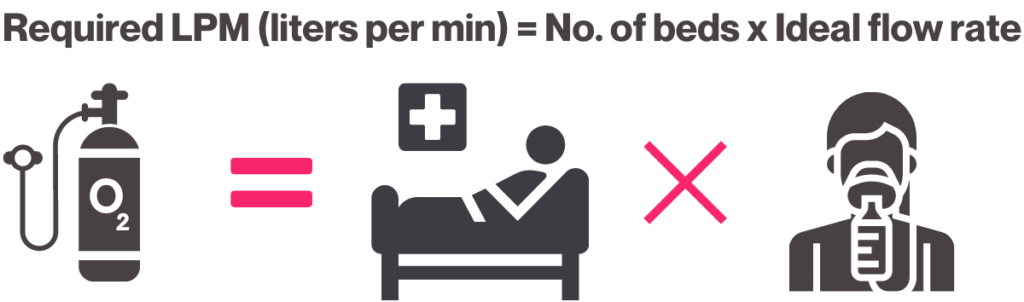

According to our research, a simplified way of estimating the capacity requirements of the O2 plant can be calculated by the following formula :

Based on this , an estimated oxygen plant capacity for hospitals of various sizes is as follows,

Note:

Medical grade oxygen can be obtained in several ways,

By liquifying air through cryogenic distillation– Oxygen is produced in air separation plants where the air is cooled and the oxygen is distilled based on its boiling point.

Through oxygen concentrators– an oxygen concentrator is designed to concentrate oxygen from ambient air. But they have limitations, technical vulnerabilities, lower life expectancy and low flow rates.

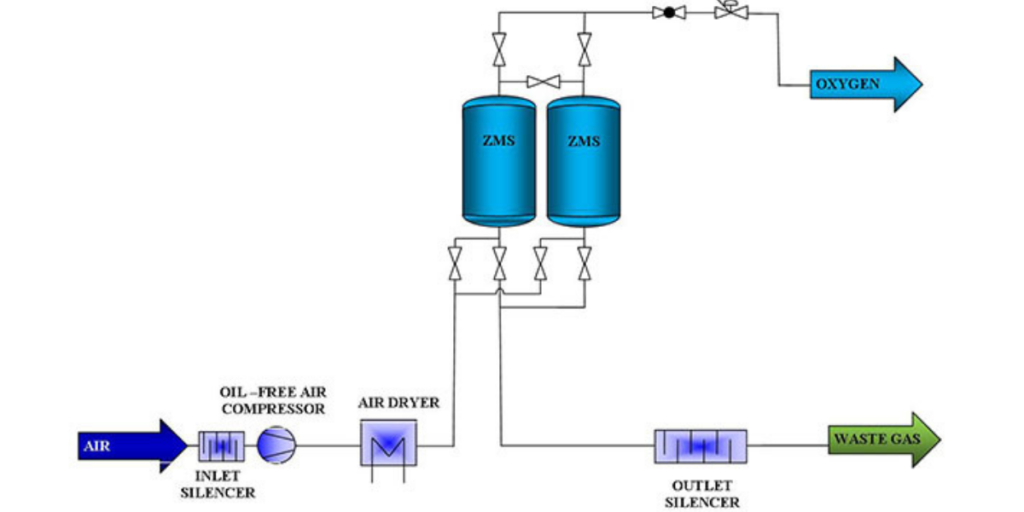

Pressure swing adsorption (PSA) units– A PSA oxygen plant employs a technology that adsorbs nitrogen from ambient air to concentrate the remaining oxygen for medical use.

Here is why setting up a PSA oxygen generation unit is the best option for hospitals,

Ambient air passes through an internal filtration system, which separates nitrogen from the air, concentrating the remaining oxygen to a high purity. It typically consists of an air compressor, dryer, filters, separation chambers, a reservoir for storage, and controls.

Area requirements: The maximum area occupied by a PSA oxygen plant of the given size is about 7ft X 9ft

Estimated costs: The average cost of setting up such a plant is approx. Rs. 80 Lakhs

To be better prepared for a possible third wave and ensure uninterrupted supply of medical oxygen, hospitals must invest in ways to reduce their dependence on the country’s oxygen producing centers, and become self-reliant.

After evaluating the various paths that hospitals could opt for, we can conclude that setting up an onsite PSA oxygen plant is the most effective and economical option.

Hospitals must look at this as an investment with not only short term, but long-term value, as it projects the hospital to be a truly independent source of quality care for its patients.